Welcome Weihai Global Chemiacl Machinery MFG Co., Ltd.!

Service Hotline

0631-5766828

Advanced Search:

CONTACT USContact Us

HOTLINE:0631-5766828

(7x24)

Mob:13061173293

Fax:0631-5766838

Tel:0631-5766938

Address:No.2, South No.1 Road, YangTing Village, HuanCui District

Lift and Flip Reacto

Your Current Location :Home

? Product

? Lift and Flip Reactor

? GSH-0.5L Hydrogenation Reactor with Ex-proof Motor and Lifting Device

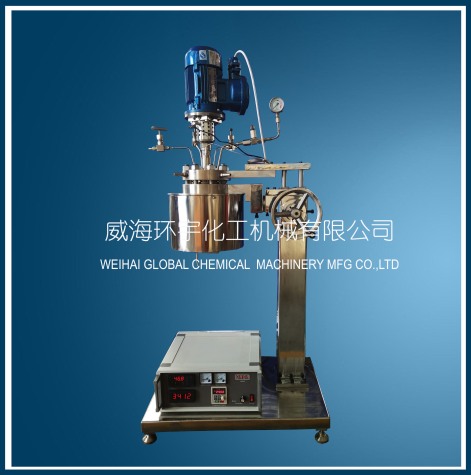

Name:GSH-0.5L Hydrogenation Reactor with Ex-proof Motor and Lifting Device

Details

Hydrogenation reactor is a stirring device for chemical reactions of gas-liquid, liquid-liquid, liquid-solid or gas-liquid-solid three-phase chemical materials. Hydrogenation reactor can fully stir various chemical materials under high pressure, temperature, high vacuum and other conditions to enhance mass and heat transfer process. Hydrogenation reactor is flammable and easy. The preferred equipment for mixing reaction of explosive, poisonous and precious media under high temperature, high pressure and high vacuum is the hydrogenation reactor, which fundamentally solves the problem of shaft seal leakage that can not be overcome by filler seal and mechanical seal before, without any leakage and pollution, long service life and maintenance-free. Carbon-manganese steel, stainless steel of various grades, titanium and titanium alloy, nickel, Hastelloy alloy, zirconium and its composite materials can be used in the autoclave body of hydrogenation reactor. The main material of hydrogenation reactor, the size, quantity, heating mode, inner structure, stirring speed and the form of impeller blade can be designed according to the user's requirements; heating mode includes jacket steam, jacket heat conducting oil electric heating, jacket oil bath cycle, far infrared and other forms for users to order. Arbitrary selection. The surface of the autoclave body with polishing requirement can reach mirror polishing level. The material with high viscosity can be processed into conical bottom, which is convenient for discharging and cleaning. According to the manufacturing structure of hydrogenation reactor, it can be divided into three categories: open flat cover reactor, open elliptical head reactor and closed reactor. Each structure has its application scope, advantages and disadvantages.

Hydrogenation Reactor, high pressure reactor, explosion proof reactor, Catalyst Reactor

Address:Yujiakuang, Yangting Town, Huancui District, Weihai City, Shandong Province

Address:Yujiakuang, Yangting Town, Huancui District, Weihai City, Shandong Province  Tel:0631-5766828

Tel:0631-5766828 E-Mail:huanyu01@wh-huanyu.com Record No:

E-Mail:huanyu01@wh-huanyu.com Record No: About Us

About Us Product

Product Contact Us

Contact Us scan code

scan code