Welcome Weihai Global Chemiacl Machinery MFG Co., Ltd.!

Service Hotline

0631-5766828

Advanced Search:

CONTACT USContact Us

HOTLINE:0631-5766828

(7x24)

Mob:13061173293

Fax:0631-5766838

Tel:0631-5766938

Address:No.2, South No.1 Road, YangTing Village, HuanCui District

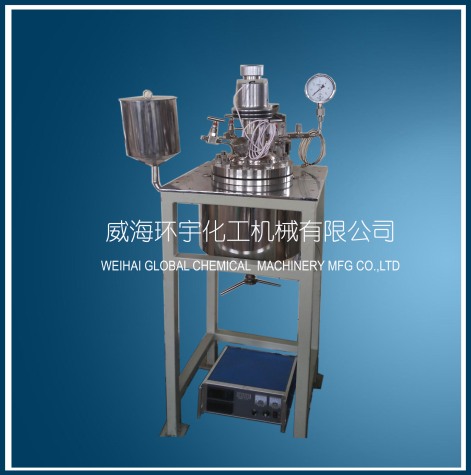

Hastelloy Reactor

Name:5L Hastelloy Reactor

Details

Hastelloy C-276 Alloy1. Physical properties

Density: 8.90g/cm3, specific heat: 425J/kg/k, modulus of elasticity: 205Gpa (21 C)

2. Corrosion resistance

Harrington C-276 alloy belongs to nickel-based alloy of nickel-molybdenum-chromium-iron-tungsten system. It is one of the most corrosion-resistant modern metal materials. It is mainly resistant to wet chlorine, various oxidizing chlorides, chloride solution, sulfuric acid and oxidizing salts. It has good corrosion resistance in low temperature and medium temperature hydrochloric acid. Therefore, in the past 30 years, in the harsh corrosive environment, such as chemical industry, petrochemical industry, flue gas desulfurization, pulp and paper making, environmental protection and other industrial fields have been widely used.

Various corrosion data of Harrington C-276 alloy are typical, but they can not be used as specifications, especially in unknown environments. It must be tested before material can be selected. There is not enough chromium in Harrington C-276 alloy to resist corrosion in strong oxidizing environment, such as hot concentrated nitric acid. This kind of alloy is mainly produced in the chemical process environment, especially in the presence of mixed acid, such as the discharge pipe of flue gas desulfurization system. The following table shows the corrosion tests of four alloys in different environments. (All welding specimens are welded by self-fluxing tungsten argon arc welding)

Lab reactor, Hastelloy Reactor, corrosion resistant reactor, acid proof reactor, acid resistant reactor, high pressure reactor, customized reactor, magnetic reactor, polymerization reactor, hydrogenation reactor, reaction kettle, pressure tank

Address:Yujiakuang, Yangting Town, Huancui District, Weihai City, Shandong Province

Address:Yujiakuang, Yangting Town, Huancui District, Weihai City, Shandong Province  Tel:0631-5766828

Tel:0631-5766828 E-Mail:huanyu01@wh-huanyu.com Record No:

E-Mail:huanyu01@wh-huanyu.com Record No: About Us

About Us Product

Product Contact Us

Contact Us scan code

scan code